A detailed account of engineering plastic & its commercial uses

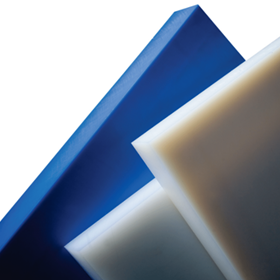

Welcome to the blog post about engineering plastic & its different uses, properties, and functions. Engineering plastics have properties that enable them to work wonders for applications used in different structures, and that, they can perform in tough & physical environments no matter what temperature it is. In structural applications, Engineering Plastics Australia has gained widespread utilization over the years.

When it comes to using plastics that can last longer in structural applications, Engineering Plastics Australia is there to help. When you compare Engineering Plastics Australia with metals, you have to acknowledge that it gives you cost-effective decoration, affordable fabrication, auto-lubrication, and transparency for a particular application.

The flexibility of Engineering Plastics Australia

The flexibility of Engineering Plastics Australia is certainly worth it in addition to other properties that you are just going to read. The fact of the matter is that plastics are not only thermo insulators but also electrical nonconductors. It depends on the usage of Engineering Plastics Australia that these properties prove to be advantageous or disadvantageous to you.

The flexibility of Engineering Plastics Australia is certainly worth it in addition to other properties that you are just going to read. The fact of the matter is that plastics are not only thermo insulators but also electrical nonconductors. It depends on the usage of Engineering Plastics Australia that these properties prove to be advantageous or disadvantageous to you.

The best part about plastics is that you can use chemical additives, fillers, and reinforcing agents to modify their structure to adjust them to the intended applications. Transmission applications, mechanical units, friction components, building construction functions, and chemical resistant units are just a few examples of engineering applications associated with plastics. In context with engineering plastics for commercial development, you see the same functional steps required.

Engineering plastics in this day & age

Marketing development, marketing research, selling, serving, and patent legal aspects are some good instances of the functional steps mentioned above. In respect of function & time, you can observe much overlap for obvious reasons. Guys carrying out each activity go through a constant interplay. There was a time when engineers were left with a range of limited options that they could use as a last resort, for instance, bronze, brass, wood, zinc, tin, copper, iron, and more.

Cellulose nitrate

It was only later that steel came into play. And then, aluminum entered the market for commercial use in bulk quantities. It is nothing but a myth that engineering plastic was first introduced in 1868. The fact is that it was not engineering plastic but it was just a semi-synthetic plastic that we know as cellulose nitrate.

Phenol formaldehyde

It was in 1909 when the first engineering plastic came into the market for commercial use. It was phenol-formaldehyde which is the first truly synthetic plastic in the history of plastic engineering. Whenever we talk about something that had excited the concepts of plastic engineering, the name of phenol-formaldehyde is always on the top of the list as it was and is an engineering material without any doubts.

It is way later the creation of phenol-formaldehyde that other plastics started to appear on the scene as a steady stream. In addition to several modifications of plastic materials, there are dozens of plastic categories out there. You can visit the above site to understand the historical significance of plastic materials that are still being used.

Comments (0)

You don't have permission to comment on this page.